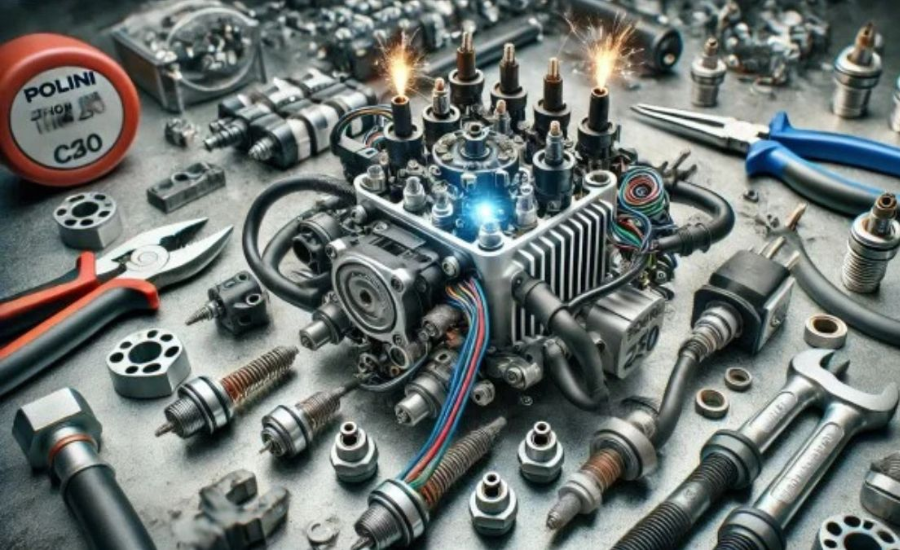

The Generic CDI for the Polini Thor 250 CDI problem has become a top pick among scooter and small motorcycle enthusiasts, celebrated for its performance, durability, and reliability. This CDI (Capacitor Discharge Ignition) unit is instrumental in optimizing engine performance, ensuring smooth and efficient operation. In this guide, we’ll dive into the benefits, functionality, installation process, and maintenance tips for the Generic CDI Polini Thor 250, giving readers a thorough understanding of this essential component.

Understanding a CDI: Key to Engine Performance

A Capacitor Discharge Ignition (CDI) system is an advanced electronic ignition mechanism commonly used in two-stroke engines, including those in motorcycles, scooters, and small vehicles. Unlike conventional ignition systems, which rely on mechanical points to generate sparks, a CDI system utilizes capacitors to store and release electrical energy with precision. When the engine needs an ignition spark, the CDI rapidly discharges the stored energy into the ignition coil, creating a powerful spark that ignites the fuel-air mixture within the engine’s combustion chamber.

The CDI system significantly impacts engine performance by managing both the timing and intensity of each spark. With its precise control, the CDI system enhances fuel efficiency, ensures smoother acceleration, and supports optimal engine power output. Properly functioning CDI units are crucial for efficient combustion, directly influencing fuel consumption, throttle response, and overall engine reliability.

The CDI unit is integral to any engine that requires precise ignition control, and understanding its role can help improve the maintenance and performance of vehicles equipped with this technology.

Polini Thor 250 CDI Troubleshooting Guide: Detailed Tips and Solutions

Renowned for its strong performance and dependable design, the Polini Thor 250 is a popular choice among paramotor enthusiasts. However, like any mechanical system, it can occasionally encounter issues, especially in models equipped with a Capacitor Discharge Ignition (CDI) system. CDI systems, while generally reliable, may experience specific problems that can disrupt engine performance. Common issues include difficulty with starting (often referred to as “hot starts”), engine misfires, rough idling, or even sudden shutdowns.

This guide provides a comprehensive look at troubleshooting and resolving these CDI-related challenges in the Polini Thor 250. Here, we’ll cover step-by-step instructions to diagnose and address each potential issue, helping you maintain a smoother, more reliable ride.

Common CDI Issues and Solutions for the Polini Thor 250

- Hard Starting or Hot Start Problems

- Symptom: Difficulty starting the engine, especially when it’s hot, can be an indication of CDI-related issues.

- Solution: Begin by checking the spark plug and ensuring it’s clean and properly gapped. A CDI system with a faulty spark plug may not deliver the necessary spark energy. Additionally, inspect the CDI connections for any loose or corroded wires.

- Misfiring and Rough Idling

- Symptom: If the engine misfires or idles roughly, this could point to inconsistent spark generation.

- Solution: Examine the CDI coil for wear or damage, as a worn coil may fail to maintain the necessary energy output. Replacing the coil can often resolve this issue. It’s also advisable to look at the grounding wire, as a poor ground connection may interfere with consistent sparking.

- Sudden Engine Shutdowns (Unfires)

- Symptom: If the engine suddenly shuts off mid-flight or during operation, a CDI malfunction might be the cause.

- Solution: Test the CDI unit with a multimeter to confirm it’s working within the specified voltage range. Over time, internal components may degrade, leading to inconsistent or complete loss of spark. If the CDI fails the test, replacing it may be the most effective solution.

By following these troubleshooting steps, Polini Thor 250 owners can more easily identify and address CDI-related issues, ensuring a reliable engine performance for safer and more enjoyable paramotor flights. Proper maintenance and prompt attention to any ignition irregularities are key to extending the lifespan and dependability of this high-performing engine.

Comprehensive Guide to Troubleshooting the CDI System in Polini Thor 250 Engines

For those new to CDI (Capacitor Discharge Ignition) systems, understanding the role of these units in the Polini Thor 250 can be challenging. This ignition system uses a capacitor to store electrical energy and releases it to the ignition coil, ensuring a spark strong enough to ignite the fuel-air mixture in the engine. As critical as the CDI unit is, any malfunction can lead to engine problems that disrupt performance and reliability. Below is an in-depth guide to identifying and resolving common CDI issues in the Polini Thor 250.

Key Signs of CDI Failure in Polini Thor 250 Engines

Several symptoms indicate potential CDI issues:

- Difficulty in starting or cranking

- Random power loss or engine stalling

- Rough engine idling and frequent misfires

- Irregular sounds or fluctuating engine speeds at idle

- Non-responsive accelerator

If you encounter these problems, the CDI system may need attention. Here are detailed steps to identify and troubleshoot CDI-related issues in the Polini Thor 250.

Step 1: Inspect CDI Connections

Loose or corroded connections are often the source of CDI malfunctions.

- Check: Examine all wires leading to the CDI for wear, corrosion, or signs of disconnection. Use a multimeter to test the continuity of the power supply to the CDI. Inconsistent voltage or unusual noises can indicate faulty wiring.

- Solution: Clean the connectors with a dry cloth to remove corrosion, tighten any loose connections, and replace any damaged wires as needed.

Step 2: Assess Grounding Connections

A poor ground connection can cause erratic engine behavior and CDI issues.

- Check: Ensure all grounding points are secure and free from rust or other obstructions.

- Solution: Clean or relocate grounding points if necessary to maintain stable electrical flow.

Step 3: Test the Ignition Coil

The ignition coil amplifies the voltage provided by the CDI to create a spark. A weak coil can result in a poor spark, leading to engine issues.

- Check: Using a multimeter, test both the primary and secondary coil resistance. Refer to the Polini Thor 250 manual for acceptable resistance values.

- Solution: Replace the ignition coil if it does not meet the recommended resistance.

Step 4: Inspect the Spark Plug

A fouled or damaged spark plug can prevent proper ignition even if the CDI and coil are functional.

- Check: Remove the spark plug and look for signs of carbon build-up, oil deposits, or physical damage.

- Solution: Clean the spark plug if it’s dirty; replace it if damaged or heavily fouled.

Step 5: Check the Flywheel and Magneto

The flywheel generates the electrical charge for the CDI. A misaligned or broken flywheel key can throw off ignition timing.

- Check: Remove the flywheel cover and inspect the flywheel key for wear or misalignment.

- Solution: Replace the flywheel key if it shows signs of damage or wear.

Step 6: Test the CDI Unit Itself

If other components are functional, the CDI box may be faulty.

- Check: Verify if the CDI is generating consistent sparks. Testing the CDI involves either using specialized testing tools or swapping it with a working unit.

- Solution: Replace any CDI box that fails to produce a consistent spark or shows signs of wear.

Step 7: Verify Engine Timing

Improper engine timing affects ignition and can lead to hard starts and misfires.

- Check: Use a timing light and refer to the Polini Thor 250 manual for timing specifications.

- Solution: Follow the manual’s instructions to adjust timing if it is out of specification.

Step 8: Check for Overheating in the CDI

Overheating is a common cause of CDI malfunction, especially with extended use.

- Check: After running the engine, touch the CDI unit to assess temperature. Excessive heat could indicate inadequate cooling.

- Solution: Improve airflow around the CDI, consider adding a heat shield, or relocate the CDI unit to reduce heat exposure.

Additional Tips for Maintaining the Polini Thor 250 CDI System

To keep the CDI system in optimal condition on the Polini Thor 250, regular maintenance and proactive care are essential. Implementing these practices can help prevent common CDI issues and improve the reliability of the engine’s ignition system. Below are key areas to focus on:

1. Regularly Inspect Electrical Connections

Electrical connections are vital for the smooth operation of the CDI system. Over time, connectors may corrode or become loose, which can lead to ignition issues.

- Action: Periodically clean all electrical connectors, removing any dirt or corrosion. After cleaning, apply a small amount of dielectric grease to the terminals to help prevent oxidation and ensure strong electrical conductivity.

2. Maintain Proper Spark Plug Gap

A well-adjusted spark plug gap ensures that the spark is strong enough to ignite the fuel-air mixture effectively. An incorrect gap can lead to misfires or weak engine performance.

- Action: Check the gap between the electrodes on the spark plug regularly and adjust as needed. Consult the Polini Thor 250 manual for the recommended spark plug gap specifications. Use a spark plug gapping tool to set the gap accurately and prevent any ignition issues related to improper spacing.

3. Monitor Engine Temperature

Excessive heat can lead to CDI malfunction, especially in high-performance engines like the Polini Thor 250. Maintaining a stable engine temperature will protect the CDI and other components from damage.

- Action: Ensure proper airflow around the engine, keep vents clear, and quickly address any cooling system issues to avoid overheating. Installing additional cooling measures or adjusting your setup can also help keep the engine temperature within an optimal range.

By incorporating these maintenance practices, you can help extend the life of the Polini Thor 250 CDI system and support a smoother, more reliable performance. Consistent attention to these details is key to preventing unexpected CDI issues and maximizing engine efficiency.

Common Causes of CDI Problems and How to Prevent or Fix Them

Capacitor Discharge Ignition (CDI) systems can sometimes encounter issues due to various environmental and mechanical factors. Here’s a closer look at typical causes of CDI malfunctions, along with recommended prevention and solutions to maintain its performance effectively:

1. Exposure to Water and Moisture

Water can severely impact a CDI unit, as moisture can cause short circuits, which may lead to complete failure of the unit’s internal components.

- Prevention and Solution: To protect the CDI from moisture damage, ensure that both the unit and all associated wiring are properly sealed. Consider using waterproof casings or applying sealant around wiring and connectors to guard against water exposure, especially in wet environments or during rainy seasons.

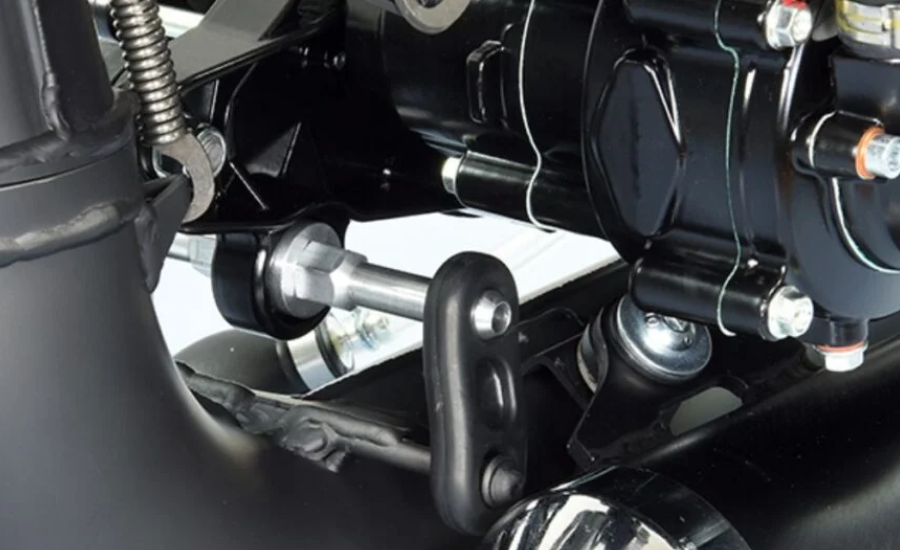

2. Vibration-Induced Damage

Over time, vibrations from the engine and road conditions can weaken connections, loosening wires or causing small internal components to shift, leading to CDI failure.

- Prevention and Solution: To minimize the effects of vibrations, install vibration dampeners around the CDI unit. Regularly inspect the fasteners and mounts securing the CDI and other components to ensure they remain tight and intact. If loose connections are detected, re-secure or replace parts as necessary to prevent future issues.

3. Overheating and High Temperatures

Excessive heat can strain the CDI, potentially leading to burnout or reduced performance, especially during prolonged use in high-temperature environments.

- Prevention and Solution: Make sure the CDI unit is installed in a well-ventilated area near the engine with adequate airflow. Adding a heat shield or relocating the CDI to a cooler spot may also help. For better heat management, consider installing a heat sensor gauge to monitor engine temperatures closely, allowing for timely intervention if temperatures begin to rise excessively.

By addressing these common causes, you can significantly improve the reliability and lifespan of your CDI system, ensuring smoother performance and reducing the risk of unexpected malfunctions. Regular inspections and proactive maintenance are essential for keeping the CDI system in top condition.

When to Consult a Professional Technician

If you’ve exhausted all troubleshooting steps and the issue with your paramotor engine persists, it may be time to consult a professional technician experienced with paramotor systems. A skilled specialist can utilize advanced diagnostic tools to identify complex issues that might not be apparent during a standard inspection. Professional assessment not only helps in accurately diagnosing hidden problems but also ensures that repairs are conducted with precision, maximizing both safety and performance for future rides.

Guidelines for Choosing Replacement Parts

When troubleshooting reveals a faulty component in your Polini Thor 250 engine, it’s crucial to replace it with parts that meet high-quality standards, ideally original or reliable aftermarket components specifically designed for this model. Using substandard or incompatible parts can lead to repeated failures, inconsistent engine performance, and increased wear on other components. Genuine or well-made aftermarket replacements ensure the engine operates as intended, preserving both reliability and longevity.

- Prioritize Compatibility: Always verify that the replacement part is fully compatible with the Polini Thor 250 model. A mismatched part, even if of good quality, can disrupt the balance and efficiency of the entire engine system.

- Seek Durability: Engine parts endure significant stress and temperature changes, so durability is key. Look for materials resistant to heat, corrosion, and wear, as these qualities enhance performance and reduce the likelihood of part breakdowns.

- Choose Reputable Brands: Stick with reputable manufacturers known for producing high-quality replacement parts. Well-known brands often have established quality control measures, ensuring each part meets certain reliability standards and specifications for optimal performance.

- Avoid Low-Quality Substitutes: While cheaper alternatives may seem tempting, they can cause recurring issues and might wear out quickly, leading to more frequent replacements and potentially costly repairs over time.

- Check Warranty and Support Options: Quality parts often come with a warranty, providing reassurance about their durability and offering potential coverage if any issues arise shortly after installation. Additionally, consider whether the brand or supplier offers customer support to assist with installation or troubleshooting.

By following these criteria, you not only safeguard your Polini Thor 250 engine’s integrity but also enjoy a smoother, more reliable ride, minimizing future repair needs and enhancing the overall engine lifespan.

Key Facts

- CDI Overview:

The Capacitor Discharge Ignition (CDI) system optimizes engine performance by storing and releasing electrical energy to create a powerful ignition spark.

- Performance Benefits:

Enhances fuel efficiency, ensures smoother acceleration, and supports optimal engine power output.

- Common Issues:

Typical CDI-related problems include hard starting, misfiring, rough idling, and sudden engine shutdowns.

- Troubleshooting Steps:

- Inspect CDI connections for corrosion or looseness.

- Check grounding connections for stability.

- Test the ignition coil’s resistance using a multimeter.

- Assess the condition of the spark plug.

- Inspect the flywheel and magneto for misalignment.

- Verify CDI unit functionality with testing tools.

- Check engine timing for accuracy.

- Monitor the CDI for overheating.

- Maintenance Tips:

- Regularly inspect electrical connections and clean them.

- Maintain proper spark plug gap.

- Monitor engine temperature to prevent overheating.

- Common Causes of CDI Problems:

Exposure to moisture, vibration-induced damage, and excessive heat can lead to CDI failures.

- Replacement Parts:

When replacing CDI components, prioritize compatibility, durability, and reputable brands to ensure optimal performance.

FAQs

Q: What is a CDI, and how does it work?

A: A CDI (Capacitor Discharge Ignition) system uses a capacitor to store electrical energy and releases it to the ignition coil, creating a strong spark for engine ignition.

Q: What symptoms indicate CDI failure in the Polini Thor 250?

A: Symptoms include difficulty starting, random power loss, rough idling, misfires, irregular sounds, and non-responsive acceleration.

Q: How can I troubleshoot CDI-related issues?

A: Troubleshooting involves inspecting connections, testing the ignition coil, assessing the spark plug, checking grounding, and verifying the CDI unit’s functionality.

Q: What maintenance should I perform on my CDI system?

A: Regular maintenance includes cleaning electrical connections, ensuring the spark plug gap is correct, and monitoring engine temperatures to avoid overheating.

Q: When should I consult a professional technician?

A: If troubleshooting does not resolve the issue, consulting a professional technician is advisable for accurate diagnosis and repair.

Related: nnrm28

Conclusion

The Generic CDI for the Polini Thor 250 is crucial for optimizing engine performance in scooters and small motorcycles. By understanding its functionality and addressing common issues through effective troubleshooting and maintenance, enthusiasts can ensure their engines run smoothly and reliably. Regular inspections and proper care can significantly extend the lifespan of the CDI system, enhancing the overall performance of the Polini Thor 250. If problems persist despite troubleshooting efforts, seeking the expertise of a professional technician is a prudent step to maintain engine reliability and performance.

Don’t let go of this: Essential Discover